PET Bottle Label Remover Machine For 99.5% Plastic Label Removing

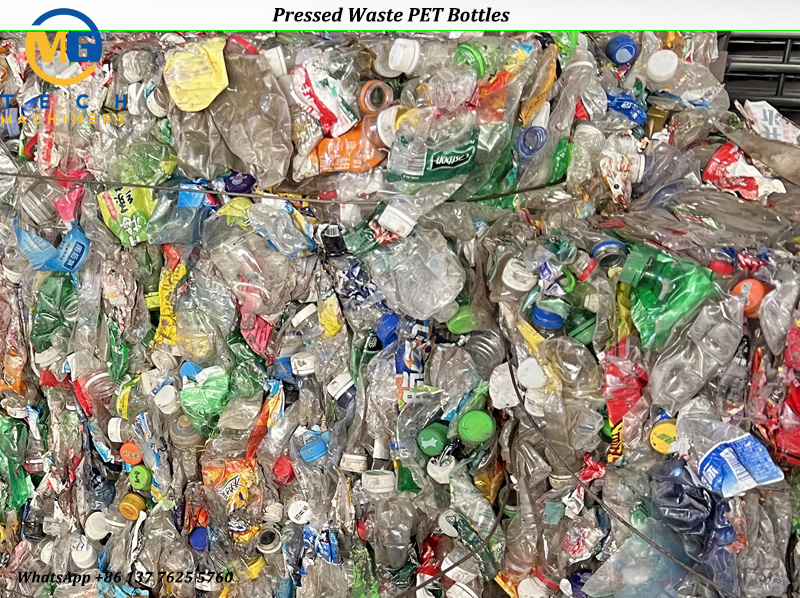

3 barrel PET bottle label remover machine, as a plastic label remover tool for high label removing rate in the waste

PET bottle recycling industry, is used to remove the PE PP PVC and PET thermal shrinkage labels from the waste PET

bottles, whether unpressed bottles or pressed bottles can be processed on the same PET bottle label remover machine.

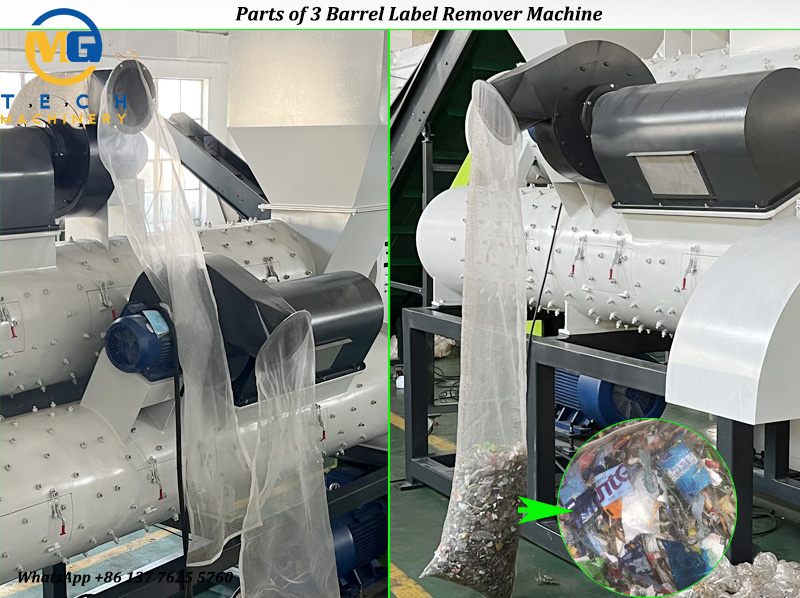

By the special designs of 3 barrels with stationary blades and three shafts with rotary blades, the final plastic label removing

rate is up to 99.5% one time for the PET bottles from the inlet to the outlet. While the blades peel off the labels in the barrels

of the label remover machine, the powerful wind system sucks out the off labels immediately from the outlets of the 3 independent

cyclone doors, and blow the labels into the collect bags.

The processing space of the 3 barrel PET bottle label remover machine is adjustable through the rotary blades and stationary blades. Therefore, It has the flexible space for bottles with different sizes from 0.3L to 3L bottles mainly for high label removing rate.

For all thermal shrinkage plastic labels, whether half labels, 3/4 labels or full labels on the waste PET bottles, the 3 barrel label remover machines have the same highest label removing rate.

Thanks to the high label removing and separating rate in the PET recycling plants, the 3 barrel type PET bottle label remover machines

can remove the most labels from the whole waste PET bottles, It help to prolong the interval time of blade sharpening for the PET bottle

crusher machine, save the usage amount of detergent in the hot washer, and reduce the wearing of main shaft and paddles in the friction

washer and screw conveyors, etc.

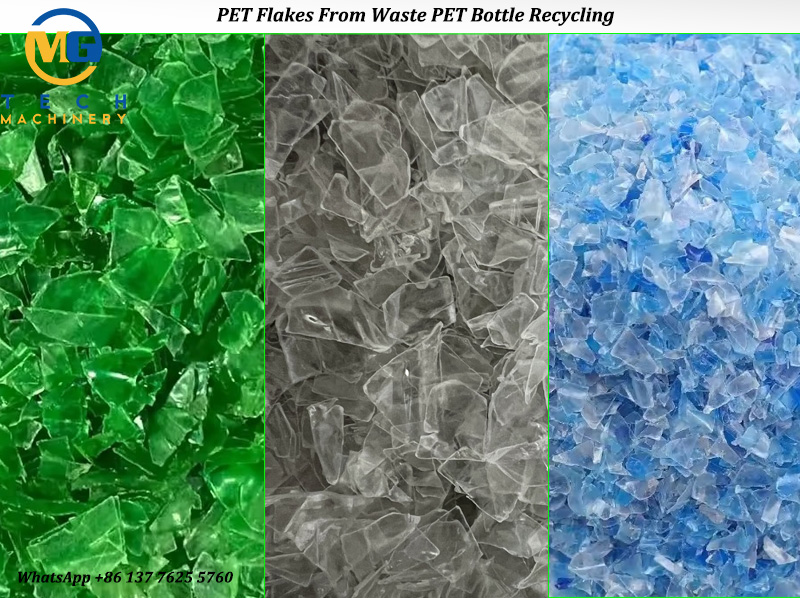

Importantly, once the PET washing line includes such 3 barrel label remover machine for recycling washing processing, the label content

of final PET flakes will be very low, so that the PET flakes can be used for injection, extrusion, blow molding, fiber making and strap production

very well.

That's why it is the most cost effective PET bottle label remover machine.

For steady label removing working, It's better to choose the correct belt conveyor for feeding the waste bottles into the 3 barrel PET bottle

label remover machines.

For more, the users can also choose our sorting table(8m, 10m or 12m, etc) to connect the outlet of the 3 barrel label remover machine,

arrange the workers do the separation of different color PET bottles manually before conveying them into the PET crusher machine.

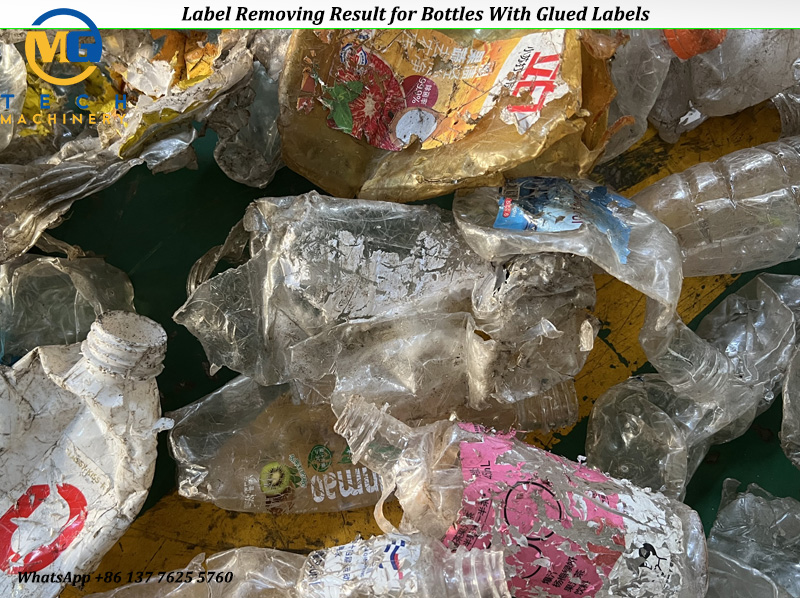

What happen for the plastic bottles with glued label?

The 3 barrel PET bottle label remover machines are used for the waste plastic bottles with all thermal shrinkage labels, it is not suitable for the bottles with glued labels.

Advantage of 3 barrel PET bottle label remover machine in MG Machinery:

1, high label removing rate, up to 99.5%.

2, wide usage for 0.3~3L PET bottles and some PE PP bottles.

3, alloy knives with long lifetime.

4, all 3 shafts are passed good dynamic balance testing.

5, special anti-blocking mechanism in cyclone system

6, strong structure for steady working.

7, famous brands for motor and electrical parts, for example, SIEMENS, DELIX, WN, etc.

8, high automation, less labor required.

9, less power consumption but large capacity.

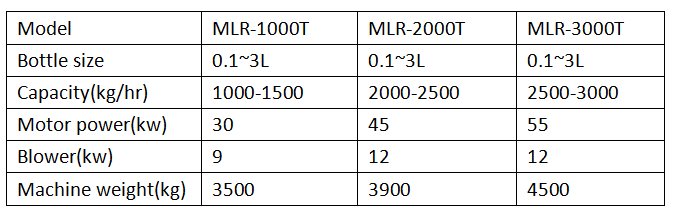

Models of 3 barrel PET bottle label remover machine in MG Machinery:

Why choose us?

1, we can provide the most suitable solution proposals according to your waste materials conditions and requirement.

2, professional design for machine flowchart and workshop layout according to your workshop area.

3, skilled and experienced workers for the machine manufacturing.

4, good testing for the machines before shipment.

5, shipment on time.

7, careful machine loading and fixing work in container.

8, dispatch engineer for after sale service in your company on time

9, training for machine and operation.

10, technology support.

etc.

Comments

Post a Comment